IIoT Control Center

The TAS Turck Automation Suite promises efficient device management in Ethernet automation networks – now with other cloud integration for location-independent real-time monitoring and troubleshooting

Quick Read

With the latest release of the TAS IIoT and service platform and the launch of TAS Cloud, the Turck Automation Suite has reached the next level. The easy-to-use toolkit for the installation, service and management of Turck devices in automation networks now also enables manufacturer-independent support and monitoring of Profinet devices thanks to new features such as the Discovery and Configuration Protocol (DCP). Profinet View allows users to recognize and configure their devices. The addition of TAS Cloud now enables continuous monitoring functions as well as cloud-based data storage and processing from any location.

In the constantly evolving world of industrial automation, the efficient management and monitoring of devices in industrial environments is becoming increasingly more important. The demands placed on software in automation technology are high, as it has to control and monitor complex processes. It must be reliable and secure, as any failure can involve considerable costs. At the same time, it must be flexible and adaptable in order to meet the changing requirements of production. Despite all its functionality, the software should nevertheless be simple and intuitive to use.

With the Turck Automation Suite, or TAS for short, Turck has developed a powerful IIoT and service platform that is increasingly establishing itself as an efficient toolbox for a host of different applications. The variety of functions goes hand in hand with a high level of user-friendliness, which makes it easier for users to manage and configure Turck devices in industrial Ethernet networks. With TAS, Turck is combining for the first time the configuration and parameterization tools of its smart sensor technology with the network management functions of its Ethernet devices centrally in a single software. The batch functions in particular speed up many operations since they can be run simultaneously for multiple network devices. This saves time, for example with firmware updates or the assignment of IP addresses. Even Codesys control programs can be managed via the network and easily loaded, saved, executed and stopped using batch processing.

Vendor-neutral support and monitoring of Profinet devices

The functionality of the IIoT and service tool increases with every update. For example, the latest release includes the Discovery and Configuration Protocol (DCP). This extends the capabilities of TAS by enabling for the first time the automatic detection and configuration of Profinet devices in a network, regardless of manufacturer, which further simplifies the setup and management of industrial automation systems. This open approach allows users to integrate a wide range of devices into their automated systems and also benefit from the advantages of the Turck Cloud.

Clear diagnostic view

The new Diagnostic View feature offers TAS users significant added value when monitoring and diagnosing faults in their systems. Specially designed for Turck devices, the Diagnostic View provides a comprehensive overview of the status of the network and displays all status messages clearly in a single view. Instead of manually checking individual devices, a single scan is all it takes to find out immediately which devices have problems. The clear display of all devices and their status messages in a single view simplifies troubleshooting considerably, especially in complex systems with many devices. With just one click, users can create a comprehensive diagnostic report that brings together in a PDF all the relevant information about a device. This report can then be sent to support for analysis and troubleshooting, further speeding up and simplifying the whole process of fault diagnosis and rectification.

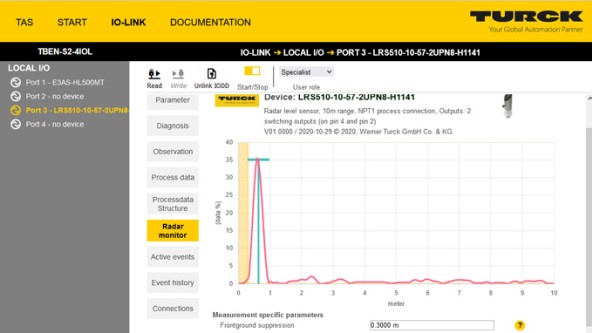

Light Curtain Monitor and Radar Monitor

Similar to other monitor apps that are accessible via the TAS platform, the Light Curtain Monitor focuses specifically on the visualization and monitoring of light curtains on site at the customer's premises. It has been specially developed for the products of Turck's optical sensor partner Banner Engineering, reliably indicates blocked light beams and allows individual configuration for optimum system performance. This function allows users to monitor the status of their light curtains in real time and quickly identify potential problems. The Light Curtain Monitor offers efficient system monitoring with functions such as light curtain alignment and the option to hide or invert certain light beams, and thus makes a significant contribution to safety and efficiency.

The Turck Radar Monitor offers similar benefits: It graphically displays the measured values of the Turck radar sensors and simplifies setup with a real-time display of the signal curve – especially when setting filters to suppress interference signals or in complex mounting situations. Users can adjust filters, measuring windows and other parameters very easily to their particular application requirements.

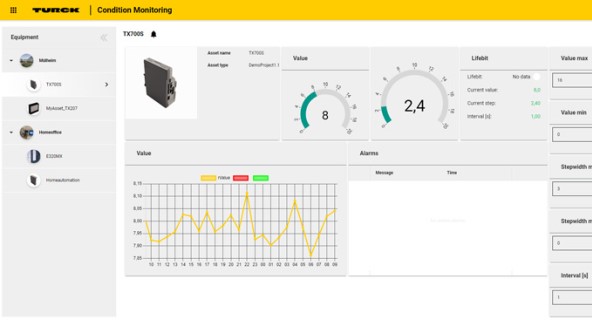

Next step: TAS Cloud

The brand new TAS Cloud now complements the existing TAS desktop solution. As part of the TAS platform, TAS Cloud offers continuous monitoring functions as well as cloud-based data storage and processing. Integration with other TAS modules and tools creates a comprehensive solution for device management, commissioning and the efficient operation of automation solutions.

The functionalities of the new solution include remote access via VPN, condition monitoring and a maintenance manager. These functions enable users to parameterize, configure and monitor their systems and devices remotely, detect maintenance requirements at an early stage and minimize downtimes. With the integration of cloud technologies, users can benefit from increased flexibility and scalability, as they can access their data anywhere and anytime.

The tenant structure of the TAS Cloud forms the foundation for highly secure and efficient data management. With up to five levels, it enables the flexible organization and categorization of data according to individual user requirements. The clear hierarchy ensures clear and organized management, allowing users to structure their data in a way that best suits their business processes. The data is physically separated strictly by client, which enables granular access control so that clients can be given specific authorizations to access their data. This protects sensitive information from unauthorized access and ensures compliance with data protection and industry-specific regulations.

Introduction Video: Turck Automation Suite (TAS)

TAS Cloud in the corporate design of the OEM

Machine builders and other OEMs who integrate TAS Cloud into their machines can design the look of the user interfaces to match their corporate design or adapt it to the corporate design of the machine purchaser. The domain and thus the URL can also be adapted to the customer's wishes.

ARGEE and BEEP View

The ARGEE logic software turns Turck's Ethernet I/O modules into IP67 logic controllers for cabinet-free operation directly in the field (field logic controller). This enables conditions and actions to be programmed very simply without any software installation required. ARGEE will not be able to replace every PLC, but the engineering software opens up new avenues in control technology, as it can relieve local networks and higher-level controllers by executing simple logic tasks. This function is unique on the market to date. TAS allows you to load ARGEE programs conveniently on a group of devices in a batch process and manage them centrally.

Backplane Ethernet Extension Protocol BEEP

TAS also simplifies the management of BEEP configurations. Turck's smart tool BEEP (Backplane Ethernet Extension Protocol) reduces the number of IP addresses required in industrial networks and simplifies the use of the TBEN and FEN20 multiprotocol block I/O modules. BEEP makes it possible to connect networks with up to 33 TBEN modules to the PLC via a single IP address in Profinet, Ethernet/IP and Modbus TCP networks. Through the reduction of the IP addresses, the user can quickly create high density I/O networks and also connect them with low cost controllers.

IO-Link apps: IODD Configurator and more

TAS also promises commissioning and management support for Turck's IO-Link apps such as IODD Configurator, Radar Monitor, Vibration Monitor, etc. The user can call up and execute the respective app directly in the special IO-Link View. The IODD Configurator, for example, can be used to parameterize IO-Link devices from all manufacturers. The app displays IO-Link process data in a graphical history curve, which is very helpful during setup. The user also has access to the plain text of all relevant parameters of the IO-Link devices used.

The Turck Radar Monitor offers similar benefits: It graphically displays the measured values of the Turck radar sensors and simplifies setup with a real-time display of the signal curve – especially when setting filters to suppress interference signals or in complex mounting situations. Users can adjust filters, measuring windows and other parameters very easily to their particular application requirements.

RFID apps: UHF demo tools

TAS also offers various tools for Turck's RFID devices, including three UHF demo tools. “Gate Applications” simulates bulk reading, in which several tags are read simultaneously in gate applications. The application ensures the reliable capture of all tags, saving time and effort that would normally be required for manual assessments. “Tag Trace” enables the determination of optimum start and stop times for read and write processes in moving applications. “Tag Population” measures the read and write performance at different positions of static objects. The UHF reader continuously increases its performance and displays the minimum power required to reliably detect the tag.

For HF RFID solutions, the “Tag Actions HF” function promises particularly convenient handling of RFID tags. This allows a user to test and execute various functions with an HF reader. This includes creating a list of read HF tags, reading information from the tag memory and the simple editing, reading and writing of data in a user-defined memory area of the tag.

There's more to come: TAS Edge

The future of Turck's IIoT and service platform TAS promises a seamless integration of TAS Desktop, TAS Cloud and the upcoming TAS Edge, which will be launched later this year. This innovative triad will enable users to make their industrial processes even more efficient and gain comprehensive control over their devices. TAS Edge will add powerful edge computing capabilities to the platform, enabling local processing of data for faster responsiveness. With this integration of desktop, cloud and edge functionalities, users have a powerful toolkit to actively shape the digital transformation of industrial automation. To meet the requirements of an IIoT platform, TAS will also support the transfer of data via MQTT and OPC UA to higher-level systems, automatic configuration routines for service tasks and many other features. TAS will considerably increase the connectivity of your production system and thus combine OT data and IT data without any barriers.

Outstanding software solution

The fact that Turck's TAS Automation Suite offers users a smart toolset for efficiently driving forward the digital transformation of industrial automation, is also demonstrated by two awards that the software has already received in its first year. TAS was named “IoT Product of the Year” at the Instrumentation Excellence Awards in the UK at the end of 2023. The Instrumentation Monthly awards recognize the best experts, products, projects and companies in the fields of testing, measurement, sensor technology and control. The readers of the German trade magazine Computer&Automation were also evidently impressed by the functionality of the Turck solution and gave TAS first place in the “Software & IT” in the “Products of the Year 2024” category.

Select Country

Turck worldwide

-turck-image.jpg)

-turck-thumbnail.jpg)