Applications

Digital Packaging Sorting with RFID

CIRCPACK by Veolia and TURCK use RFID technology to make the sortability of packaging measurable – and provide manufacturers with valuable data for sustainable packaging development

Car Body Identification in Automobile Production

End-to-end use of RFID for automobile identification

RFID Solution for Data Acquisition in Stator Production

Chinese electric motor manufacturer ensures quality and traceability of stator production by using Turck's RFID system to track the workpiece carriers

UHF RFID Tunnel for Goods Identification on Conveyor Belts

Complete package for setting up read tunnels simplifies reliable identification of RFID tags and returnable load carriers in logistics and production

Checking Hose Connections with RFID

B. Braun Medical AG guarantees reliable mixing and filling processes through fail-safe verification of hose connections in ATEX zone 2 – with an RFID solution from Turck

Reliable RFID Access Control for Inspection Robots

At the BASF plant in Antwerp, a four-legged inspection robot ensures the safety of the water treatment plant – and Turck's RFID solution ensures its reliable access to the charging station

Logistics: RFID Reduces Error Quota by 99 Percent

Building materials supplier Ahlsell drastically reduces delivery errors and increases sustainability in the supply chain with a powerful RFID complete solution

RFID: ROI Achieved After Three Avoided Delivery Errors

For a plastic pipe manufacturer, the RFID solution for the comprehensive control of loading and delivery processes pays off after just three delivery errors are avoided

Sustainable Tracking of RTIs thanks to RFID

Logistics services provider Recalo monitors its pool of returnable transport items (RTI) with a track and trace solution from Turck Vilant Systems and thus reduces its customers' CO2 footprint

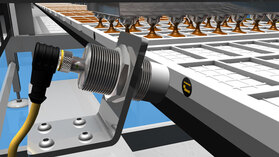

RFID System Identifies Solar Cell Carriers

Chinese solar cell manufacturer uses Turck's RFID system to increase the quality and efficiency of its production

Carrier Identification in Electronics Manufacturing

Turck's identification solution for miniature workpiece carriers ensures precise single tag detection and increased efficiency in smartphone production

Modular Plant for Flexible and Efficient Production

Smart Automation developed a modular production line with decentralized control for an automotive supplier – from sensors to multiprotocol I/O modules, pre-assembled connection technology, LED lights right through to RFID

RFID with HF Bus Mode Eases Seed Storage

KWS optimizes and secures its seed production with Turck’s RFID solution for the wireless identification and temperature monitoring of silo boxes – Profinet S2 redundancy included

RFID Tracking of Battery Raw Materials with OPC UA

RFID system from a single source guarantees reliable processes – even with high throughput and complex and varying processes

RFID Solution with Smart Forklifts in Autombile Production

RFID solution with smart forklifts and IT integration via middleware from Turck Vilant Systems ensures reliable and fast goods flows in Chinese automotive plant

RFID Enables Unmanned Store at Major Building Site

Using an RFID system solution from Turck Vilant Systems, wholesaler chain ProMart developed the “EasyMart” shop concept – self-service containers or store rooms that make fixing materials and tools available at any time and on any site

RFID Support Enables Track and Trace in Food Production

Turck’s BL ident RFID system secures the traceability along the manufacturing and distribution chain of a Chinese food producer

Tracking Big Bags with RFID

Extensive control over the production and delivery process of assets as well as full compliance with legal requirements

Shipment Tracking for Raw Materials

Material transparency called for Sandvik to introduce an automated inbound processes with RFID

RFID-based Shipment Control Minimizes Errors

Jysk ensures delivery accuracy by fully automated tracking of position and direction movement of outgoing pallets

Error-free JIS Order Picking for Bumpers

UHF RFID tracking beyond trade and company boundaries ensures batch size one for automotive suppliers and OEMs

RFID-based Tracking of Inbound and Outbound Materials

ABB realizes 60 percent productivity growth by digitalizing their production including material flow tracking with an UHF-RFID system directly linked to the company’s SAP

Access Control for Protected Areas

Stand-alone RFID system reliably protects against unauthorized access to secure areas

RFID Bus Mode Ensures Quality of Lithium-Ion Batteries

Bus mode combines a high data transfer rate with a low cost per read position

Access Control with RFID System

Turck's IO-Link RFID system secures high-voltage tests at the Belgian railroad SNCB

RFID Control of Tube Connections in the Ex Area

Encapsulated HF reader identifies connections directly in Atex Zone 1/21 and transfers data to Ethernet gateways in Zone 2/22

Decentralized Package Verification

Retrofittable RFID tracking system eliminates errors from the packaging process

Selective Asparagus Harvester

AvL Motion is breaking new ground – with a machine for the selective harvesting of white asparagus, 'garnished' with high precision sensors as well as RFID and fieldbus technology from Turck

RFID System Increases Efficiency in Copper Pipe Production

A Chinese manufacturer monitors the production process for copper pipes with a Turck RFID system with decentralized control using BL20 gateways

Fast Tag Detection at Warehouse Gates

Multiplex operation with external antennas on RFID UHF read/write head Q180

Item-level Detection with UHF RFID

Near-field antennas and Q300 for individual detection throughout the production cycle

Decentralized monitoring of cooling stations

RFID system and decentralized logic guarantee high production quality of cable harnesses

Identification of Mobile Containers

With the BL ident RFID system from Turck, mobile containers can be checked without the need to open them

Identification of Chocolate Molds

With the help of the RFID-technology, chocolate molds are able to control their individual chocolate production processes. The molds tell the depositing machine how they are to be filled and the washing machine how they are to be cleaned.

Press Shop

The combination of RFID and inductive proximity switches ensures smooth production workflows and prevents costly down times

Paint Shop

Custom high-temperature data carriers are resistant to the aggressive chemicals in dip tanks, as well as to the high temperatures in drying ovens

RFID and I/O modules for Safe Tool Changes

Kirschenhofer Maschinenbau GmbH, the special machine manufacturer, guarantees safe tool changes for truck catalytic converters with Turck’s BL ident I/O system and TBEN-S I/O modules

Unique Products on the Conveyor Belt

Sonplas uses Turck's BL ident RFID system and uprox+ sensors in an assembly plant for injector nozzles

Select Country

Turck worldwide

_rdax_280x157p.jpg)